Forward thinking is an obligatory – it’s never early enough for innovations

A company that rests on its laurels is sure to fall behind. This philosophy forms the basis of the innovative spirit you have experienced with ELTEN for decades. Thanks to many of our own developments, we have always been able to set new standards in occupational safety. Ground-breaking innovations such as ERGO-ACTIVE, SAFETY-GRIP, BIOMEX PROTECTION© or BIOMEX DYNAMICS have been created by our own development experts in cooperation with universities, high-tech research facilities and medical specialists from established sports medicine institutes. We are already working on ambitious visions of the future such as the “intelligent“ dynamic safety shoe.

Our soles, our field of expertise

A decisive criterion fort the safety and well-being of a shoe-wearer is the quality of the outsole of his shoe. Material, tread depth and tread design must be in line with the respective application area. Numerous variants are possible here − depending on the peculiarities and specific conditions of a workplace. We help you to find the right sole so that you are perfectly equipped for your work.

Tread design

An ergonomic tread rib configuration ensures improved rolling and guards against fatigue. Rounded tread edges provide for safe footing on the ground.

Tread depth

Sufficient height of the individual tread bars is particularly important on uneven surfaces. Deep treads deliver superb grip.

MONO VS. DOUBLE DENSITY

The major advantage of double-layered soles is that two different materials can be used here. For example, the outsole can be produced from rubber and the midsole from PU. This combines the advantages of both materials: The superb heat resistance of rubber and the comfortable impact absorption properties of PU. In contrast, the advantage of a single-layered sole lies in the fact that a single material can be injected with a lower density. This results in a lightweight sole, which conforms well to the ground characteristics.

INDOOR OR OUTDOOR?

Entirely diverse requirements arise when shoes are used indoors or outdoors, due to the different ground properties. Indoor floors are often smooth hall floors, where slipping prevention is particularly important. The sole should guard against the risk of slipping, whilst also supporting easy turning on the floor. Soles for outdoor workplaces should provide particular protection against twisting on uneven grounds and should also ensure secure footing on wet/frozen ground.

Regardless of which material: Our soles are non-slip or slipresistant according to requirements, depending on the tread design and depth. Many have been given the best possible non-slip rating SRC − approved by independent test institutes.

RUBBER Sohle-Gummirobust and heat-resistant

Rubber outsoles are exceptionally sturdy: short-term temperature-resistant up to 300°C, tough to penetrate by sharp-edged objects and resistant to fuel, oil, microbes and numerous chemicals. Special manufacturing processes make them abrasion-resistant. However, rubber is heavier than PU and TPU, and is somewhat less flexible at cold temperatures.

POLYURETHANE (PU)Sohle-Polyurethan flexible and sturdy

PU outsoles can withstand temperatures of up to 130˚C and are flexible at temperatures down to – 30˚C. Similarly to rubber soles, they are resistant to oil and fuel, numerous chemicals and microbes, and are abrasion-resistant, although they are much lighter. Particular advantage of the material: the good impact absorption characteristics for cushioning foot comfort.

THERMOPLASTIC POLYURETHANE (TPU)Sohle-TPU extremely abrasion-resistant

The characteristics of TPU outsoles are comparable to those of PU outsoles in many aspects. Yet they are – as a result of a special manufacturing process – even more efficient. Thanks to a reduced abrasion they are more durable, and also their non-slip properties are stronger. Another advantage of TPU outsoles: their higher elasticity and resistance to the cold.

OPTIMAL CHARACTERISTICS FOR OUTDOOR WORKS

01 BEVELLED PROFILE RIBS Particularly good grip on uneven substrates. Increased stability and exceptional non-slip properties: This is made possible by tread ribs, which are bevelled in the stopping or push-off direction. This makes the safety shoe highly versatile in every weather and on difficult substrates. 02 ERGONOMIC ROLLING An S-line runs through the entire outsole tread and supports the natural rolling action of the foot: Setting the heel down on the outer edge, rolling over the mid-foot in the direction of the ball of the foot – a movement that precisely follows an S-line. 03 FLEX GROOVES They facilitate improved physiological rolling of the foot and easier physiological bending during kneeling activities. 04 LIMITING THE RISK OF STUMBLING AND TWISTING Both ends of the sole exhibit a negative profile, which prevents „sticking“, in particular with turning movements and when setting the foot down. 05 OUTSTANDING SELF-CLEANING CHARACTERISTICS The configuration of the tread bars encourages the independent loosening of dirt, or makes it easy to knock out. Good self-cleaning characteristics optimise slip-resistance. 06 TOE PROTECTION FOR A LONG SERVICE LIFE An overcap from polyurethane (PU), which is moulded during the sole fitting process, offers exceptional protection against wear in the toe area and in doing so extends the service life.

OPTIMAL CHARACTERISTICS FOR WORKING IN INDOOR AREAS

01 HONEYCOMB Increased slip resistance on smooth industrial floors. These ensure good slip resistance and optimum stability when standing. 02 PIVOT POINTS in the sole reduce frictional resistance during rotation to a minimum. 03 TORSION ELEMENT Effective prophylaxis against stumbling and twisting in the centre of the outsole. This stabilizes the outsole in the midfoot area and supports the de-coupling of the front and rear of the foot to avoid twisting. It also reduces the risk of injuries and overstraining. 04 FLEX GROOVES They facilitate improved physiological rolling of the foot. Kneeling activities are also easier due to physiological bending. Furthermore, they effectively support forward movement. 05 NEGATIVE PROFILE The sole is rounded at the outer edges, and both ends exhibit a negative profile, which decisively reduces the risk of „sticking“, in particular with turning movements and when setting the foot down. 06 S-LINE Less fatigue at turning/standing workstations. Natural rolling occurs in this way: Setting the heel down on the outer edge, rolling over the mid-foot in the direction of the ball of the foot. This movement precisely follows an S-line. It is reflected in the design of the outsole. 07 PARTICULARLY THICK MIDSOLE LAYER Industrial floors are also smooth and hard: Full impact absorption with soft PU core significantly improves the load cushioning. This is especially important when working whilst standing with constant strain on the joints.

BIOMECHANICAL ROLLING MOTION SUPPORT

Inspired by nature: Biomechanics serves as example for Biomex Dynamics outsoles! When looking at joints, muscles and bones, the human foot follows certain movement patterns while walking. Our Biomex Dynamics outsole supports these and enables a dynamic forward movement inside the shoe, which is identical to the congenital walking movement.

NATURAL MOVEMENT DYNAMICS WHEN WALKING BAREFOOT The torsion is the natural ability of the foot to roll through an S-shape from the rear to the front of the foot. This allows the human foot to adjust to the smallest instances of unevenness in the ground. GUIDE ELEMENTS The decoupling guide elements parallel to the S-shaped rolling line support the torsion and therefore the rolling dynamic of the front and rear foot. PROPHYLAXIS AGAINST FOOT FATIGUE If the foot musculature is subject to even stresses then this has a positive effect on the guidance and stability of the joints too (ankle, knee and hip joints). This reduces the risk of injury and makes a contribution to counteracting degenerative diseases (osteoarthritis in the knee and hip joints).

BIOMECHANICAL ROLLING MOTION SUPPORT

Inspired by nature: Biomechanics serves as example for Biomex Dynamics outsoles! When looking at joints, muscles and bones, the human foot follows certain movement patterns while walking. Our Biomex Dynamics outsole supports these and enables a dynamic forward movement inside the shoe, which is identical to the congenital walking movement.

NATURAL MOVEMENT DYNAMICS WHEN WALKING BAREFOOT The torsion is the natural ability of the foot to roll through an S-shape from the rear to the front of the foot. This allows the human foot to adjust to the smallest instances of unevenness in the ground. GUIDE ELEMENTS The decoupling guide elements parallel to the S-shaped rolling line support the torsion and therefore the rolling dynamic of the front and rear foot. PROPHYLAXIS AGAINST FOOT FATIGUE If the foot musculature is subject to even stresses then this has a positive effect on the guidance and stability of the joints too (ankle, knee and hip joints). This reduces the risk of injury and makes a contribution to counteracting degenerative diseases (osteoarthritis in the knee and hip joints).CHALLENGING COMBINATION WORKPLACE When it comes to workplaces where standing and walking activities are roughly at equal, the challenge lies in the fact that maximum non-slip properties bring an abrupt halt to the dynamic of rotational movement during upright activities.

01 FOUR PIVOT POINTS The solution! The pivot points in the sole decisively reduce frictional resistance during rotational movements. 02 BEVELLED TREAD BARS By bevelling the tread bars in the stopping or push-off direction, very good anti-slip properties take effect according to the ELTEN Safety-Grip concept. 03 S-LINE The configuration of the tread bars follows an S-line, which supports the physiological rolling of the foot. 04 FLEX GROOVES The S-line effect is reinforced by additional flex grooves. Bending during kneeling activities is also easier that way. 05 NEGATIVE PROFILE The sole is rounded off at the outer edges, and both ends exhibit a negative profile, which acts to prevent „sticking“ – in particular with workplace-typical turning movements and when putting the foot down.

REVOLUTIONARY CUSHIONING – PROVIDES MORE ENERGY ON HARD GROUND

01 BEVELLED PROFILE RIBS Particularly good grip on uneven substrates. Increased

stability and exceptional non-slip properties: This is made possible by tread ribs,

which are bevelled in the stopping or push-off direction. This makes the safety shoe

highly versatile in every weather and on difficult substrates.

02 ERGONOMIC ROLLING An S-line runs through the entire outsole tread and supports

the natural rolling action of the foot: Setting the heel down on the outer edge,

rolling over the mid-foot in the direction of the ball of the foot – a movement that

precisely follows an S-line.

03 FLEX GROOVES They facilitate improved physiological rolling of the foot and

easier physiological bending during kneeling activities.

04 LIMITING THE RISK OF STUMBLING AND TWISTING Both ends of the sole exhibit a

negative profile, which prevents „sticking“, in particular with turning movements

and when setting the foot down.

05 SOLE CORE MADE OF INFINERGY® FROM BASF Cushions impacts and bounces back into its

original shape extremely well when the pressure is being reduced, thus the energy is

transferred back to the wearer.

06 HONEYCOMB Increased slip resistance on smooth industrial floors. These ensure

good slip resistance and optimum stability when standing.

All the best for your feet, All the best for you

Many people develop foot problems during their lifetime. It is often unnecessary to seek orthopaedic treatment for these. However, pain certainly draws attention to them, also whilst at work. Our personalised semi-orthopaedic insoles for safety shoes can provide help in such cases, before minor issues become orthopaedic problems. However, if an orthopaedic complaint has developed then special orthopaedic insoles or inserts are essential. In case of doubt always seek advice from the treating physician.

Every foot is different

People's feet are as varied as the people themselves. However, there are three types which occur more frequently than others. In order to support the particular foot types efficiently, we have developed three different types of inlay soles. Each has a different level of arch support.

Low

Support for flat feet and for comfortable shock absorption.

Medium

For significantly more comfort for medium arches.

High

For effective shock absorption if the foot arch is too high.

ELTEN SensiCare

ELTEN SensiCare inlay soles close the space between the foot profile and the flat bottom of the shoe; they have a preventive effect as regards pain.

Currex workpro

The latest sports science knowledge has been integrated into the patented Currex Soles technology.

Wellness made to measure

A temperature-sensitive foil determines the individual foot form and the particular footprint with its significant problem areas.

Orthopaedic Foot Protection

Foot protection is essential for workers in hazardous environments. Our orthopaedic foot protection collection is designed to provide maximum comfort and safety.

Our Materials

Quality makes the subtle difference. High quality materials make a sustainable contribution to well-being and to the longevity of the shoe–one good reason why we only work with selected partners, who make these materials available to us for the production of our products. We work with leather and high-tech materials, which satisfy the maximum demands.

Leather

Animal hide is a material that is produced 100% naturally. Its properties determine the quality of the leather it produces. Significant variations in quality can arise even with the same leather. Special processes during tanning and finishing can further improve positive production characteristics. Leather is characterized by its good breathability, longevity, stability of form, and simultaneous flexibility. All substances used in the production of our leather are subject to strict legal specifications.

TEXTILE MATERIALS AND HIGH-TECH FIBRES

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, special functions such as moisture absorption/release or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances and kind to skin. In many workplaces, metal-free safety shoes are essential. And those allergic to leather also play it safe when opting for a pure textile product. They offer greater scope than leather, because they are much more versatile in terms of structure and surface configuration. ELTEN therefore utilises high-tech materials from leading international manufacturers.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

We work together with the leather tannery Heinen in Germany. Here, top quality leather is produced according to the highest social and ecological standards. By purchasing safety shoes produced from Terracare® leather, you actively support the reduction of CO2-emissions.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

Cordura® is a high-quality fabric woven with polyamide fibers. This material is very light and breathable. Thanks to its extreme tear and abrasion resistance, Cordura® is very suitable to be an upper material. In addition, it is dirt- and water-resistant and dries quickly.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

Shoes with a GORE-TEX® membrane permanently protect your feet against moisture, are extremely breathable and provide optimale climate comfort control.

ALL-WEATHER-MEMBRAN

Shoes with GORE-TEX® Performance Comfort are especially suitable for working outdoors in normal to cold temperatures thanks to a low insulation.

WINTER-MEMBRGore_Winter-MembranAN

Shoes made with GORE-TEX® Insulated Comfort are particularly good for use in rain, snow and cold temperatures. With maximal heat insulation the foot will remain warm.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

NOMEX® by DuPont™ is a high-strength fibre made of a patented mix of 95% NOMEX® and 5% KEVLAR®, high-strength aramid. NOMEX® offers optimum flame resistance, heat protection and chemical resistance. It is selfextinguishing, will not melt nor drip, its fire resistance is not affected by cleaning.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

We use high-quality textiles with exceptional characteristics when it comes to moisture absorption and release. Our inner linings are skin-friendly and achieve a long service life.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

Optimal absorption and release of moisture by way of a breathable lining. The microfibre spacer fabric effects a capillary action for significantly better moisture transport. The 3D structure is thermo insulating and the pump effect ensures high air permeability and breathability.

Textile materials and high-tech fibres

Textile materials used in the production of shoes must withstand particular challenges. Wear-resistance, longevity, and special functions such as moisture absorption or water-tightness are required here. They should also be environmentally friendly, free of hazardous substances, and kind to skin. In many workplaces, metal-free safety shoes are essential. Those allergic to leather can also play it safe when opting for a pure textile product.

The right fit

The number one rule when selecting the right shoe: It must fit! This is even more important with shoes that are used daily and for many hours at a time – work shoes. If the foot protection gives cause for complaints because the fit is wrong then it may end up left on the shelf. If the shoe is worn despite this then painful or tired feet become a distraction during work, potentially also posing a risk to safety – for both the wearer and their colleagues. ELTEN has therefore set itself the target of providing all workers with safety footwear that fits them perfectly, regardless of age and gender.

Optimum fit for pros

Safety risks at the workplace need to be avoided at all times – also for the feet. Comfortable safety shoes are an important part of PPE. But how can the perfect shoe make it onto the foot? The answer: by a technically high end measuring system and the thus gained recommendations for foot protection with optimal fit. And exactly in this area we have researched and developed intensively.

Ladies Fit

Our ladies fit shoes provide the right balance of comfort and protection. Specifically designed to fit the unique shape and needs of women’s feet, they offer superior grip, support, and flexibility for all-day use in demanding environments.

FOR THE SPECIAL CASES

With a number of safety shoes we offer you a comfortable multi-width system, which creates the individually required space for every foot: Through greater volume in the forefoot area. We have also adjusted the toe protection cap accordingly. It has “grown together” with the width and offers effective protection because it also covers the toe area well at the sides, whilst the requisite remaining height is still intact.

WE’VE GOT THE REAL DEAL

ELTEN has been working intensively with research experts for many years now. And that is bearing fruit. For example, the ERGO-ACTIVE system with its various fits was developed within the framework of mutual research work with Tübingen University. Despite being the same shoe size, one in every three feet is somewhat stouter than average, whilst another may be considerably wider. With such deviations from the “average width fitting”, the shoe size is the right length but the foot protection still does not fit correctly. It is too tight and does not fit with the varying width-dependent foot proportions either. If the shoe is worn regardless then the feet become painful. Or the wearer selects a shoe that is too long, which brings with it a risk of tripping. Our answer: the creation of a tailored multi-width system in cooperation with Tübingen University, through which we are able to offer every wearer “their own” shoe.

BIGGEST AND BEST FOOT FORWARD – NO PROBLEM!

ELTEN SAFEGUARD offers space for individuals whose feet are not only very wide but also particularly voluminous. With a spacious ball dimension, a particularly wide toe cap and extra space in the instep, they offer sufficient space for all those who live with larger feet.

LADIES’ FEET HAVE DIFFERENT PROPORTIONS

Researchers found that there are different length-dependent types of female feet in the size ranges 35 – 36, 37 – 39 and 40 – 42, each with their own specific proportions. Small feet are predominantly stout, medium feet tend to be wide, and large feet are usually narrow. The results of these findings are three small-scale production lasts, on which the NOVA-FIT models have been built.

Even more comfort

Comfort is a decisive criterion when selecting the right safety shoe. The level of concentration at work can be massively influenced if the wearer does not feel comfortable in his shoes or if these even cause pain. And of course, that distraction can lead to accidents. Uncomfortable shoes are unpopular. We therefore ensure not only the safety of the shoe wearer but also the maximum possible comfort and well-being.

In contrast to working areas where activities predominantly take place whilst seated, conventional workplaces bring with them increased strain on the ankle, knee and hip joints, as well as the back, due to constant standing, walking and kneeling for many hours. Very hard floors are frequently also a factor here. When selecting the correct individual degree of cushioning it is always necessary to bear the specific workplace in mind. Because the foot is stressed in the heel and ball area when standing, and across its entire area when walking, the whole area of the foot should ideally be cushioned in a work shoe. Alongside the use of high quality materials with good durability and resistance to fatigue, a soft, embedding insole is particularly important.

ERGONOMIC SYSTEM FOR MORE FOOTHOLD

The support system consists of a cuff that surrounds the rear of the foot and the heel and is connected to the sole. It is integrated into the shoe‘s lacing system and, together, they create a firm yet flexible tension belt system. By stabilising the heel bone, the system increases the foot‘s stability. One of the greatest risks of accidents on the floors of production facilities, twisting, is reduced significantly in this way.

An entirely new wearing experience: Shoes without irritating seams. That offers major advantages. The shoe can be even better aligned with the natural shape of the foot. Furthermore, painful and distracting pressure points caused by seams are no longer an issue. And if no seam exists then these cannot tear under high stresses. And the shoe wearer enjoys yet one more benefit: The shoes are easier to clean, because if there are no seams then these cannot retain dirt. A welcome „side effect“: The shoes simply look good for longer!

BOA® – is an innovative closure system without laces, buckles or Velcro fasteners, which holds all day long without loosening. Because once the system has been latched in place, laces and reels stay in position without re-tightening! Particular advantage: The closure can be closed and opened with one hand. Annoying dangling laces are no longer a problem and can no longer trip the wearer up. And BOA® functions at lightening speed.

To ensure that the shoe feels perfectly comfortable, ELTEN has come up with something special: a built-in chassis with integrated heel cap for greater stability in the sole and heel area. It increases the height of wearer‘s foot slightly with a simultaneously flatter appearance of the outsole in the heel area, thereby also improving wear comfort. Furthermore, the shoe also has a more feminine look. The chassis is not visible, but is instead permanently integrated inside the shoe.

Ergo-Active inlay soles guarantee the optimum wearer comfort-aligned with the personal requirements of the wearer. We therefore produce them in three comfort classes, which differ in terms of hardness and fit: Ergo-Active inlay soles are available in Soft, Medium and Strong and for three foottypes. In order that each wearer can enjoy the cushioning and comfort he really deserves. Thanks to the ESD equipment, Ergo-Active are also suitable for use at workplaces where electrostatic discharges can cause damage to sensitive parts.

SPECIAL DANGERS

What else do we have up our sleeve? Everything required for foot protection! There are workplaces with something more – namely their very own risk. Because they are electrosensitive or thermally challenging. Or because the feet need to be protected against the dangers of cutting, twisting on awkward grounds and other special hazards. We have also developed the perfect shoes for this.

PROTECTION AGAINST CUTS FROM CHAINSAWS

A 100% protection against cuts from hand-held chainsaws can’t be ensured by personal protective equipment (PPE). However, experience has shown that it is possible for PPE to be designed so as to give a very high degree of protection. Among others, the protective effect can be achieved by the following functional principle: slow down (PPE) the chainsaw by using fibers with high cut resistance–these fibers absorb the chainsaw speed’s kinetic energy. It is very important that the pants overlap the shoes. A cut-resistant shoe of class 2 can withstand a chainsaw speed of 24 m/s.

In metal-sensitive work places especially high demands are made to employees‘ workwear. For instance, for work at security gates or in the vicinity of induction loops of the kind used at airports or in industry completely metalfree safety shoes are a basic requirement. There safety shoes with metal components like steel caps or soles would interfere with sensitive metal detectors. A composite toe cap and plastic eyelets or fabric lace parts are used in place of the usual metal fittings.

A cut-resistant interlining stops materials with sharp edges from reaching the foot. The material consists of the following traits: shape-retaining, high tear-resistance and large flexibility. The result is cut-resistance and high-protective effects against mechanical risks.

D3O® is an intelligent, shock-absorbing material. Its molecules draw together to form a „network“ when impacted by a foreign body, and distribute the kinetic energy.

PROTECTION AGAINST HEAT RISKSAND SPRAY FROM MELTED METAL

This standard is a supplement to EN ISO 20345. EN ISO 20349 adds protection against heat risks and spray from melted metal so that the shoe meets minimal requirements for founders and welders. Among other requirements, casting boots are particularly tested for their resistance against the effects of melted metal. Shoes that pass the fluid aluminium test receive an “Al”; and those that pass the fluid iron test receive an “Fe”. All the labels known from EN ISO 20345 remain unchanged.

PROTECTION AGAINST CUTS FROM CHAINSAWS

A 100% protection against cuts from hand-held chainsaws can’t be ensured by personal protective equipment (PPE). However, experience has shown that it is possible for PPE to be designed so as to give a very high degree of protection. Among others, the protective effect can be achieved by the following functional principle: slow down (PPE) the chainsaw by using fibers with high cut resistance–these fibers absorb the chainsaw speed’s kinetic energy. It is very important that the pants overlap the shoes. A cut-resistant shoe of class 2 can withstand a chainsaw speed of 24 m/s.

EVEN MORE SAFETY

Foot protection from ELTEN: That means safety according to European standards–and protective equipment, the components of which cater precisely for the various potential hazards in the workplace. Naturally in accordance with the latest technology and certified according to protection classes 1, 2 and 3. However, good foot protection must fulfil further criteria.

At dawn, dusk, night or in bad weather conditions people in dark clothing are firstly recognized when they are only 30 meters away. The equipment with reflective materials offers additional protection and helps you to be seen under all weather and light conditions.

ESD DOES NOT EQUAL ESD

ESD shoes should be used if there is a necessity to conduct electrostatic charge away in a controlled manner through the shoes. ESD approved safety shoes and occupational shoes thus protect not only personnel, but also provide protection for components and assemblies at risk from electrostatic energy.

THE RELEVANT STANDARDS FOR ESD FOOTWEAR ARE:

DIN EN 61340-5-1 “Protection of electronic components from electrostatic phenomena”. Here the person/footwear system is tested whereby a max. limit value of 35 MΩ (3.5 x 107 Ω) must be complied with. DIN EN 61340-4-3 “Standard test procedure for special applications: footwear”. The testing of the footwear can be carried out in 3 different climate classes. The lower the relative humidity, the more problematic the effects on the capability to carry the static charge away. All ELTEN ESD shoes are approved per climate class 1 – preconditioning the shoe at max. 15 % relative humidity. Of the 3 climate classes, this test represents the highest requirements on the capability of the shoe to carry the static charge away. This ensures that the ELTEN ESD shoes meet the highest expectations of our customers in practical situations, even under difficult climatic conditions.

ELTEN fits its safety shoes of classes S1P and S3 either with a non-metallic penetration-resistant midsole or a steel midsole. Both types meet the supplementary requirements for penetration resistance in accordance with EN ISO 20344/20345. For greater penetration resistance, e.g. in the construction industry, we recommend using S3 safety shoes with steel midsoles.

TRUNCATED NAIL

The penetration resistance is measured in the laboratory using a truncated nail

of diameter 4.5 mm and a force of 1100 N. Higher forces or nails of smaller

diameter will increase the risk of penetration occurring. In such circumstances

alternative preventative measures should be considered.

Two types of penetration resistant insert are currently available in PPE

footwear. These are metal types and those from nonmetal materials. Both types

meet the minimum requirements for penetration resistance of the standard marked

on the footwear but each has different additional advantages or disadvantages

including the following:

METAL

Advantage: Steel midsoles are less affected by the shape of the sharp object (i.e. diameter, geometry) or hazard (i.e. sharpness). Disadvantage: Due to shoemaking limitations they do not cover the entire sole area of the shoe (about 85%).

NON-METAL

Advantage: Non-metallic penetration resistant midsoles may be lighter, more flexible and provide a greater coverage area when compared with steel midsoles. Disadvantage: The penetration resistance may more likely depend on the shape and the size of the pointed object..

Toe protection caps are available in a range of fits. Our models for wider feet are naturally also equipped with toe protection caps with greater volume, whilst the ladies’ models contain toe protection caps with a slimmer fit. As such, the right toe protection cap is available to suit almost every foot shape.

STEEL TOE CAPS

Steel toe caps are more stable than caps produced from other materials. Steel toe caps are also break-resistant under high loads. They have a slimmer appearance than composite toe caps for example.

Two types of penetration resistant insert are currently available in PPE footwear. These are metal types and those from nonmetal materials. Both types meet the minimum requirements for penetration resistance of the standard marked on the footwear but each has different additional advantages or disadvantages including the following:COMPOSITE TOE CAPS

Composite toe caps are approx. one third lighter than steel toe caps and therefore save weight. They are particularly well suited for areas in which no metal is permitted.

ALUMINIUM CAPS

Aluminium toe caps are approx. 40 % lighter than steel caps and are therefore comparable with plastic caps, although they result in a much slimmer look because they achieve the same protective effective with a reduced material thickness. Aluminium caps are particularly suitable for use in winter, thanks to their low temperature conductivity.

NORMS OVERVIEW

The standards which we apply to our products are as stringent as the quality guidelines of the companies we deliver to. ELTEN is a company with a quality management system certified to DIN EN ISO 9001.

Of course, all ELTEN safety shoes are manufactured in accordance with EN ISO

20345 and thus offer the wearer the highest mandatory protection level. They are

equipped with a corrosion-resistant safety toe cap for high stress (pressure /

impact loading of 200 joule). Furthermore, ELTEN also sticks to some additional

requirements mentioned in the old DIN EN 345, which stipulated even higher

quality standards.

SB

all basic demands are met.

S1

all basic demands are met.

On top of this, the following additional requirements are fulfilled:

+ closed heel part also for low shoes,

+ antistatic,

+ energy assimilation at the heel part.

S2

all basic demands of S1 are met.

On top of this, water permeability and water vapour absorption are fulfilled.

S3

all basic demands of S2 are met.

On top of this, profiling of the cutsole and the application of a

penetration-protecting sole.

It is important that safety shoes be chosen for the established protection

requirements and the corresponding area of use. A suitable shoe must be chosen

on the basis of a hazard analysis. You can also receive detailed information

about this at the corresponding mutual indemnity associations.

The labeling has the following meaning:

EN ISO 20345 Safety Shoe Requirements / EN ISO 20347 Work Shoe Requirements

SB/OB Basic shoe

S1/O1 Basic shoe ; supplemental: closed heel area, antistatic, heel energy

absorption

S2/O2 Basic shoe ; supplemental: closed heel area, antistatic, heel energy

absorption, water penetration and absorption resistance

S3/O3 Basic shoe ; supplemental: closed heel area, antistatic, heel energy

absorption, water penetration and absorption resistance, penetration resistance,

treaded sole

P Penetration resistance

A Antistatic shoe

E Heel energy absorption

HI Heat insulation

CI Cold insulation

HRO Resistance to high heat

WRU Water penetration resistant uppers

CE TESTED

CE Labelling means that for all ELTEN safety shoes, type examination certificates are available. ELTEN thereby testifies the conformity with the European guidelines and confirms that ELTEN safety shoes have been submitted to all relevant testings.

Together with internationally renowned designers, our in-house and outside development teams follow their creations from the first drafts through the numerous wearing test at the early prototype stage on to production and finally market launch. Our designs are highly contemporary without following short-lived fashions and they are tailored to meet the needs of the various fields for which they are intended. A safety shoe for a building worker looks different from protective footwear for a fire-fighter. What’s more, our women’s models are designed on a special women’s shoe last that takes into account the specific physical characteristics of a woman’s foot, rather than being simply based on the same last as men’s shoes, as is so often the case. A host of awards and appreciations prove that good, distinctive design is something we take seriously. Because ELTEN shoes adapt and change – just like the people who wear them.

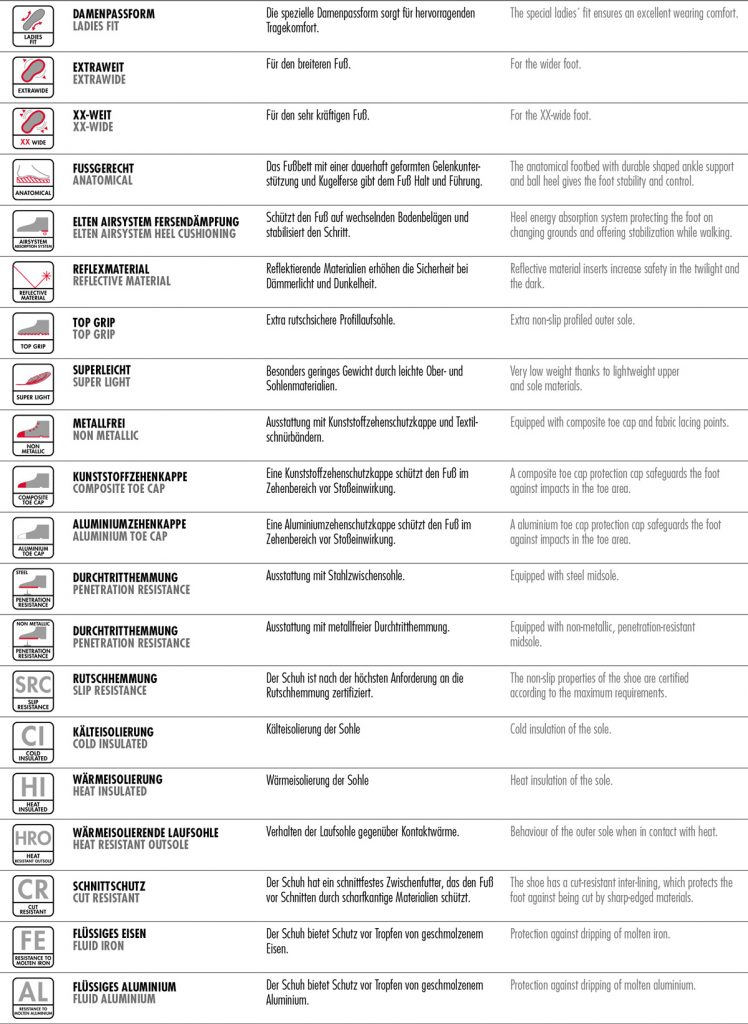

Pictograms